The Honeywell Pro 3000 Thermostat is a reliable, non-programmable digital device designed for easy temperature control. It features a large, backlit display for clear readability in any lighting condition, making it user-friendly and efficient for homeowners seeking straightforward climate management solutions.

1.1 Overview of the Honeywell Pro 3000 Series

The Honeywell Pro 3000 Series is a line of non-programmable digital thermostats designed for simplicity and reliability. Manufactured by Resideo Technologies, these thermostats are part of the Honeywell Home product family, offering straightforward temperature control for residential use. The series includes models like the TH3110D and TH3210D, supporting 1 Heat/1 Cool and 2 Heat/1 Cool systems, respectively. Known for their large, backlit displays, these thermostats provide clear visibility in various lighting conditions. They are engineered for easy installation and operation, making them a practical choice for homeowners seeking efficient climate management without advanced programming features. The Pro 3000 Series is backed by Honeywell’s reputation for durability and energy-efficient performance.

1.2 Importance of the User Manual

The user manual for the Honeywell Pro 3000 Thermostat is an essential resource for understanding and operating the device effectively. It provides detailed instructions for installation, temperature adjustment, and maintenance, ensuring optimal performance and safety. The manual also covers troubleshooting common issues, helping users resolve problems without professional assistance. By following the guidelines outlined in the manual, users can maximize energy efficiency and extend the lifespan of the thermostat. Additionally, it includes warranty information and customer support details, offering peace of mind and assistance when needed. The manual is available for download in PDF format, making it easily accessible for reference at any time. Proper use of the manual ensures the Honeywell Pro 3000 functions as intended, delivering reliable climate control for your home.

Installation of the Honeywell Pro 3000 Thermostat

Installation involves removing the wallplate, mounting the thermostat, and connecting wires according to the manual. Ensure proper wiring and refer to the guide for specific instructions.

2.1 Pre-Installation Checklist

Before installing the Honeywell Pro 3000 Thermostat, ensure you have the following items ready: the thermostat unit, wallplate, mounting screws, and wires. Turn off the power to your HVAC system at the circuit breaker. Verify the system type (heat, cool, or heat pump) to ensure compatibility. Remove the old thermostat carefully, noting wire labels for proper connection. Dispose of any mercury-containing thermostats responsibly, as required by regulations. Check for any damaged wires and repair them if necessary. Ensure the wall surface is level and clean for proper mounting. Refer to the manual for specific wiring diagrams and system requirements to avoid installation errors. This preparation ensures a smooth and safe installation process.

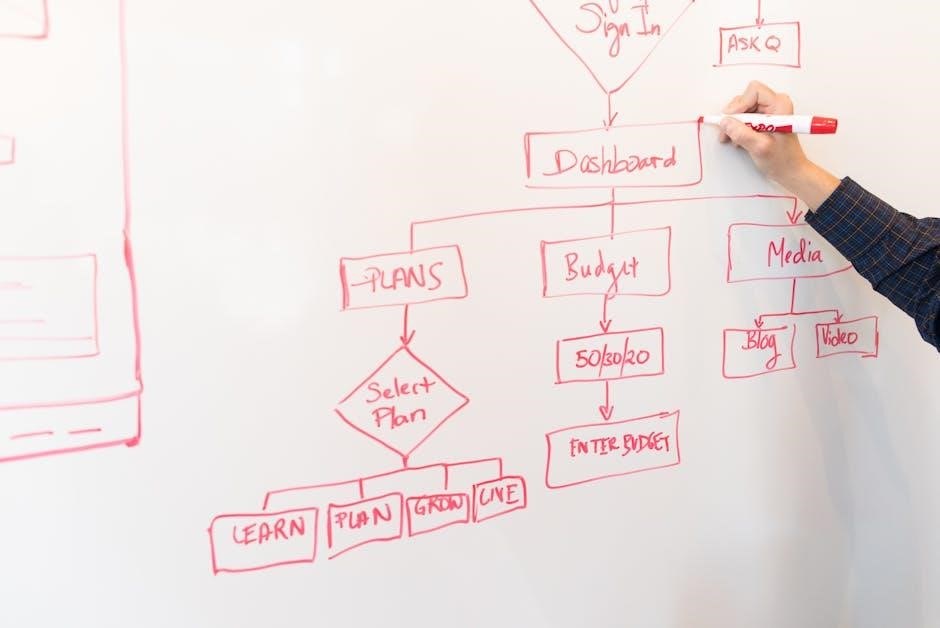

2.2 Step-by-Step Installation Guide

Turn off the power to your HVAC system at the circuit breaker before starting the installation.

Remove the old thermostat and label the wires according to their functions (e.g., R, W, Y, G, C).

Mount the new wallplate on the wall, ensuring it is level and secure.

Connect the wires to the appropriate terminals on the wallplate, referring to the wiring diagram in the manual.

Attach the Honeywell Pro 3000 Thermostat to the wallplate by aligning the hooks and gently snapping it into place.

Turn the power back on at the circuit breaker and test the system to ensure proper operation.

Adjust the system switch to “Heat,” “Cool,” or “Fan” to verify functionality.

Refer to the manual for additional settings or configurations.

This guide ensures a safe and efficient installation process for your Honeywell Pro 3000 Thermostat.

2.3 Mounting and Wiring Instructions

Remove the old thermostat and label the wires for identification (e.g., R, W, Y, G, C).

Mount the wallplate on the wall, ensuring it is level and secure.

Connect the wires to the corresponding terminals on the wallplate, matching the wiring diagram in the manual.

Attach the Honeywell Pro 3000 Thermostat to the wallplate by snapping it into place.

Ensure all connections are secure and double-check the wiring configuration.

If the old thermostat contains mercury, dispose of it properly according to local regulations.

Turn the power back on and test the system to confirm proper operation.

This step-by-step guide ensures a safe and accurate mounting and wiring process for your Honeywell Pro 3000 Thermostat.

Key Features of the Honeywell Pro 3000 Thermostat

The Honeywell Pro 3000 Thermostat features a large, backlit display for easy readability, a non-programmable design for straightforward operation, and a system switch for heat, cool, and fan modes.

3.1 Non-Programmable Digital Thermostat

The Honeywell Pro 3000 is a non-programmable digital thermostat, offering simplicity and ease of use. It allows manual temperature adjustments with up and down buttons, ensuring precise control. The thermostat is designed for basic heating and cooling systems, providing consistent comfort without advanced scheduling features. Its straightforward interface makes it ideal for users who prefer direct control over their environment without complicated settings. The non-programmable nature ensures reliability and reduces the learning curve, making it accessible for all users. This feature caters to those who value ease of operation and immediate adjustments, perfect for homes with steady temperature needs.

3.2 Large Backlit Display

The Honeywell Pro 3000 Thermostat features a large, backlit display that ensures easy readability in any lighting condition. This bright, illuminated screen provides clear visibility of both the current and set temperatures, making it convenient to monitor and adjust settings. The backlit feature is particularly useful in low-light environments, eliminating the need for additional lighting sources. This display enhances user experience by offering a straightforward and visually appealing interface. Its clarity and size make it accessible for users of all ages and tech-savviness. The backlit display is a standout feature, contributing to the thermostat’s overall ease of use and modern design. It ensures that controlling your home’s temperature is both simple and efficient, day or night.

3;4 System Switch (Heat/Cool/Fan)

The Honeywell Pro 3000 Thermostat features a System Switch that allows users to easily transition between heating, cooling, and fan-only modes. This switch is a key component for controlling your HVAC system, enabling you to select the desired operation based on your comfort needs. The Heat mode activates your heating system, while the Cool mode engages the air conditioning. The Fan mode circulates air throughout your home, even when heating or cooling is not active. This switch provides flexibility and precise control over your indoor climate. Its intuitive design ensures seamless operation, allowing you to customize your environment with minimal effort. The System Switch is a vital feature that enhances the overall functionality of the thermostat, making it a practical solution for managing your home’s temperature efficiently.

Operating the Honeywell Pro 3000 Thermostat

The Honeywell Pro 3000 operates with ease, allowing temperature adjustment via up/down buttons, system switch selection for heat/cool/fan modes, and fan control for air circulation.

4.1 Temperature Adjustment

Adjusting the temperature on the Honeywell Pro 3000 Thermostat is straightforward. Use the up and down buttons to increase or decrease the desired temperature. The thermostat will display the set temperature and the current room temperature. Ensure the SYSTEM switch is set to HEAT or COOL before making adjustments. The thermostat will automatically adjust the heating or cooling system to reach the selected temperature. For precise control, press and hold the buttons for faster temperature changes. The large, backlit display ensures visibility, even in low-light conditions. Always confirm the temperature adjustment by checking the display. Proper temperature settings optimize comfort and energy efficiency. Regularly review and adjust settings to match your preferences and seasonal needs.

4.2 Using the System Switch

The Honeywell Pro 3000 Thermostat features a SYSTEM switch that allows you to select the operating mode: HEAT, COOL, or FAN. To use the SYSTEM switch, slide it to the desired position based on your comfort needs. In HEAT mode, the thermostat activates the heating system to warm your home. In COOL mode, it engages the cooling system to lower the temperature. The FAN mode allows the fan to run continuously or automatically, improving air circulation. When in FAN mode, use the FAN switch to choose between “Auto” (fan runs only when heating or cooling) or “On” (fan runs continuously). Always ensure the SYSTEM switch is set to the correct mode for proper operation. The display will indicate the active mode, ensuring accurate temperature control. Regularly review and adjust the SYSTEM switch to meet your comfort preferences. Proper use enhances energy efficiency and system performance.

4.3 Fan Control Settings

The Honeywell Pro 3000 Thermostat offers two fan control settings: Auto and On. In Auto mode, the fan operates only when the heating or cooling system is active, optimizing energy use and reducing unnecessary airflow. This mode is ideal for maintaining consistent temperatures while minimizing fan noise. The On mode allows the fan to run continuously, providing constant air circulation, which can help distribute heat or cool air evenly throughout your home. To adjust the fan settings, use the FAN switch located on the thermostat. Selecting the right mode ensures efficient operation and enhances comfort. Always check the display to confirm the fan mode, ensuring it aligns with your desired settings. Proper fan control contributes to better indoor air quality and system efficiency.

Maintenance and Troubleshooting

Regularly clean the display and check wiring connections. Replace batteries when low. For issues, reset the thermostat or check circuit breakers. Ensure proper system power and verify temperature settings for accurate operation.

5.1 Replacing Batteries

To replace the batteries in your Honeywell Pro 3000 Thermostat, first ensure the system is powered off. Open the thermostat’s front cover by gently pulling it away from the wall. Locate the battery compartment, typically at the rear of the thermostat. Remove the old AA alkaline batteries and insert the new ones, ensuring proper orientation. Replace the cover securely. If the thermostat does not turn on, check the batteries for correct installation. For models like TH3110D or TH3210D, this process remains consistent. Always use high-quality batteries to maintain reliable performance. If issues persist, consult the user manual or contact Honeywell support for assistance.

5.2 Resetting the Thermostat

Resetting the Honeywell Pro 3000 Thermostat can resolve various operational issues. Start by removing the AA alkaline batteries from the battery compartment. Press and hold the reset button (if available) for 5-10 seconds. Reinstall the batteries and wait for the thermostat to restart. For models like TH3110D or TH3210D, this process resets all settings to factory defaults. If no reset button is present, simply removing the batteries for 30 seconds will achieve a similar effect. After resetting, you may need to reconfigure your preferred settings. If the issue persists, refer to the user manual or contact Honeywell customer support for further assistance. Regular resets can help maintain optimal performance and troubleshooting efficiency.

5.3 Common Issues and Solutions

Common issues with the Honeywell Pro 3000 Thermostat often relate to connectivity or sensor accuracy. If the thermostat does not turn on, ensure the circuit breaker is functioning and batteries are properly installed. For temperature inaccuracies, clean the display and sensors to ensure proper detection. If the system does not respond to temperature adjustments, verify that the SYSTEM switch is set correctly (Heat, Cool, or Fan). If issues persist, reset the thermostat by removing batteries for 30 seconds or pressing the reset button. Consult the user manual or contact Honeywell customer support for further troubleshooting. Regular maintenance and updates can prevent recurring problems and ensure optimal performance.

Additional Resources and Support

For further assistance, visit customer.resideo.com or call Honeywell Customer Care at 1-800-468-1502. Download the user manual from manualzz.com for detailed guidance.

6.1 Downloading the User Manual

The Honeywell Pro 3000 Thermostat user manual is readily available for download from various sources. Visit customer.resideo.com or manualzz.com to access the PDF version. The manual provides comprehensive guidance on installation, operation, and troubleshooting. It includes detailed instructions for temperature adjustment, system switch usage, and fan control settings. Additionally, the manual covers maintenance tips, such as battery replacement and resetting the thermostat. For convenience, the document is available in multiple languages and can be downloaded free of charge. Ensure you refer to the correct model-specific manual for accurate information. This resource is essential for maximizing the functionality and longevity of your Honeywell Pro 3000 Thermostat.

6.2 Customer Support Contact Information

For assistance with your Honeywell Pro 3000 Thermostat, contact Resideo Technologies, Inc. Customer Care at 1-800-468-1502 (toll-free). Visit their official website at customer.resideo.com for support resources, troubleshooting guides, and FAQs. International customers can find regional contact details on the Resideo website. Representatives are available to address installation, operational, and maintenance inquiries. Additionally, the Honeywell Home trademark is licensed from Honeywell International Inc., ensuring reliable support for all products. Utilize these resources to resolve issues promptly and ensure optimal performance of your thermostat.

6.3 Warranty Information

The Honeywell Pro 3000 Thermostat is backed by a limited warranty provided by Resideo Technologies, Inc. This warranty covers the product against defects in materials and workmanship for a period of one (1) year from the date of purchase. The battery is excluded from this warranty. For warranty service, contact Resideo Customer Care at 1-800-468-1502 or visit customer.resideo.com. Proof of purchase is required to process warranty claims. The Honeywell Home trademark is used under license from Honeywell International Inc., ensuring high-quality standards and reliable customer support. This warranty provides assurance of durability and performance for your thermostat.