The Plantronics W02 Series offers a reliable wireless communication solution, designed for seamless connectivity and enhanced audio performance, ideal for professional environments and everyday use.

1.1 Overview of the Plantronics W02 Wireless Headset System

The Plantronics W02 Wireless Headset System is a multi-device connectivity solution designed for seamless communication. It features Bluetooth pairing, advanced audio quality, and a sleek design for professional use. The system includes a base unit and headset, offering extended range and long battery life. It supports connectivity to desk phones, mobile devices, and computers, making it versatile for office environments. With intuitive controls and a lightweight design, the W02 series enhances productivity while ensuring crystal-clear sound quality for calls and multimedia applications.

1.2 Key Features of the W02 Series

The W02 Series boasts advanced Bluetooth connectivity, enabling seamless pairing with multiple devices. It features crystal-clear audio, long-lasting battery life, and a lightweight, ergonomic design for comfort. The system supports wireless freedom with extended range and intuitive controls, enhancing user experience. Additional features include noise cancellation, voice clarity, and customizable settings, ensuring optimal performance. These features make the W02 Series a reliable choice for professionals seeking a high-quality wireless communication solution.

1.3 Benefits of Using the Plantronics W02

The Plantronics W02 Series provides enhanced convenience and productivity, offering users a seamless communication experience. With its advanced features, it ensures high-quality audio and reliable connectivity, minimizing distractions; The long-lasting battery life and ergonomic design promote all-day comfort, while the intuitive controls simplify operation. Its multi-device compatibility and easy setup further enhance versatility, making it ideal for both office and remote work environments. These benefits ensure the W02 Series is a practical and efficient solution for professionals seeking a dependable wireless headset system.

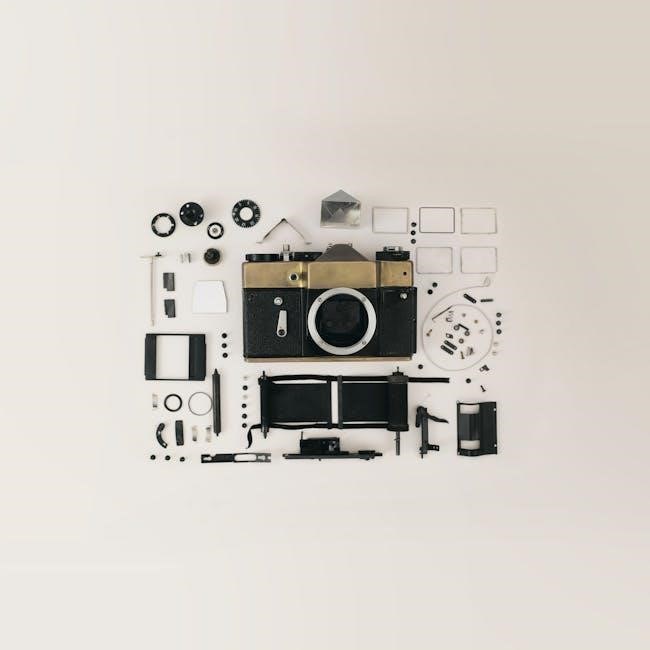

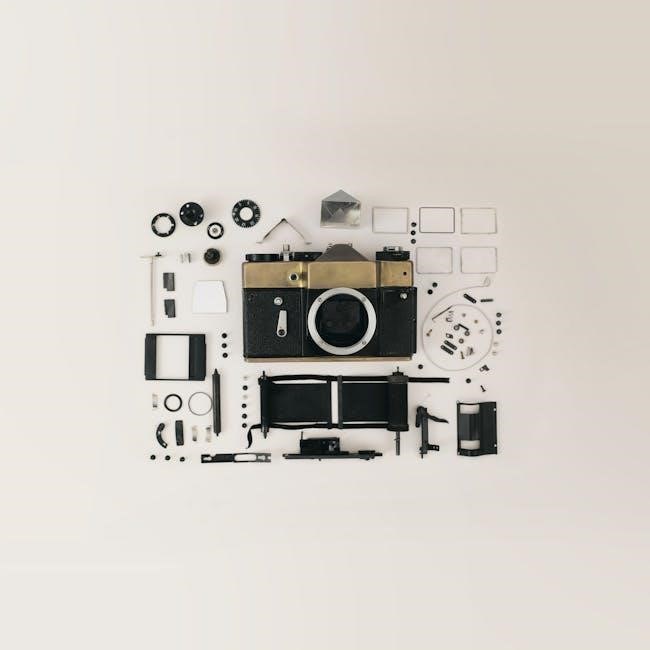

System Components and Accessories

The Plantronics W02 system includes a sleek base unit, lightweight headset, and essential accessories like charging cables and ear tips for a complete setup.

2.1 Base Unit Overview

The Plantronics W02 base unit serves as the central hub, offering advanced Bluetooth connectivity, intuitive controls, and LED indicators for pairing and charging status. It supports multi-device connections, ensuring seamless switching between calls and audio sources. The base also houses the charging dock for the headset, providing convenient power management. Designed for durability and ease of use, it complements the headset to deliver a reliable communication experience. With its compact design, it fits neatly into any workspace, enhancing productivity without compromising style.

2.2 Headset Overview

The Plantronics W02 headset is ergonomically designed for comfort and durability, featuring high-quality audio reproduction and noise-canceling technology. It offers multiple wearing styles, including over-the-head and behind-the-ear options, to suit individual preferences. The headset includes intuitive controls for call management, volume adjustment, and mute functionality; With advanced audio enhancements, it ensures crystal-clear sound in various environments. The rechargeable battery provides extended talk time, making it ideal for all-day use. Its lightweight construction and sleek design contribute to a seamless user experience, catering to professionals seeking reliable and comfortable communication solutions.

2.3 Additional Accessories and Parts

The Plantronics W02 system includes various accessories to enhance functionality and customization. These include charging stations, USB cables, and power adapters for convenient charging. Additional ear tips and headbands are available for personalized comfort and fit. Replacement parts like microphone windscreens and battery compartments ensure longevity. Optional accessories such as desk stands and carrying cases provide added convenience. These components are designed to optimize performance, durability, and user satisfaction, ensuring a tailored experience for diverse communication needs.

Setting Up the Plantronics W02

The setup process begins with unboxing and connecting the base unit, followed by pairing the headset and configuring settings using the provided quick start guide for a smooth experience.

3.1 Unboxing and Initial Setup

Begin by carefully unboxing the Plantronics W02 system, ensuring all components, including the base unit, headset, and accessories, are included. Next, connect the base unit to a power source and allow it to charge fully. Insert the battery into the headset and ensure it is properly aligned with the base for initial pairing. Refer to the quick start guide for step-by-step instructions on powering on the devices and initializing the pairing process. This setup ensures a smooth and efficient start to using your wireless headset system.

3.2 Connecting the Base Unit

Connect the Plantronics W02 base unit to a power source using the provided cable. Ensure the base is placed on a stable surface and away from interference sources. Plug the power adapter into a nearby outlet and confirm the base unit powers on. The LED indicator will light up, signaling it is ready for use. For optimal performance, position the base unit in an area with minimal obstructions. Refer to the user manual for specific placement recommendations and troubleshooting tips to ensure a stable connection and reliable operation of your wireless headset system.

3.3 Pairing the Headset with the Base

To pair the headset with the base unit, ensure both devices are powered on. Press and hold the pairing button on the base until the LED indicator flashes. Next, activate the pairing mode on the headset, typically by holding its power button until its LED also flashes. The base and headset will automatically connect once pairing is successful. If pairing fails, reset both devices and retry. Refer to the user manual for detailed instructions and troubleshooting tips to ensure a secure and stable connection between the headset and base unit for optimal performance.

Pairing and Connectivity Options

The Plantronics W02 supports Bluetooth and multi-device connections, enabling seamless pairing with mobile phones, computers, and other compatible devices for efficient communication and flexible use.

4.1 Bluetooth Pairing Instructions

To pair your Plantronics W02 headset, press and hold the Bluetooth pairing button on the base unit for three seconds. The indicator light will flash red and blue, signaling pairing mode. Once the headset is detected, it will automatically connect, and the light will turn solid blue. For mobile devices, enable Bluetooth and select the W02 from the available devices. Follow the on-screen prompts to complete the pairing process. This ensures a secure and stable connection for high-quality audio communication. The W02 supports multi-device connectivity, allowing seamless switching between phone calls and other devices.

4.2 Connecting to a Mobile Phone

To connect your Plantronics W02 headset to a mobile phone, enable Bluetooth on your device. Place the headset in pairing mode by holding the Bluetooth button until the indicator flashes. Search for available devices on your phone and select “Plantronics W02.” Follow the on-screen instructions to complete the pairing process. Once connected, you’ll hear a confirmation tone. The W02 supports hands-free calls and audio streaming, ensuring a seamless mobile experience. The connection remains stable within a range of up to 33 feet, offering freedom to move while on calls.

4.3 Managing Multiple Device Connections

The Plantronics W02 supports multi-device connectivity, allowing users to pair up to two devices simultaneously. To manage connections, pair the headset with your primary device, such as a mobile phone or computer, by enabling Bluetooth and following the pairing process. Once paired, the W02 automatically connects to the last paired device. To switch between devices, simply activate the Bluetooth function on the desired device. The headset’s LED indicator will confirm the active connection. This feature ensures seamless transitions between calls and audio sources, enhancing productivity in dynamic environments. The W02 maintains a stable connection within a range of up to 33 feet.

Customizing Your W02 Experience

Customize settings, audio preferences, and firmware updates to optimize performance, ensuring a tailored experience that meets individual needs for enhanced functionality and user satisfaction.

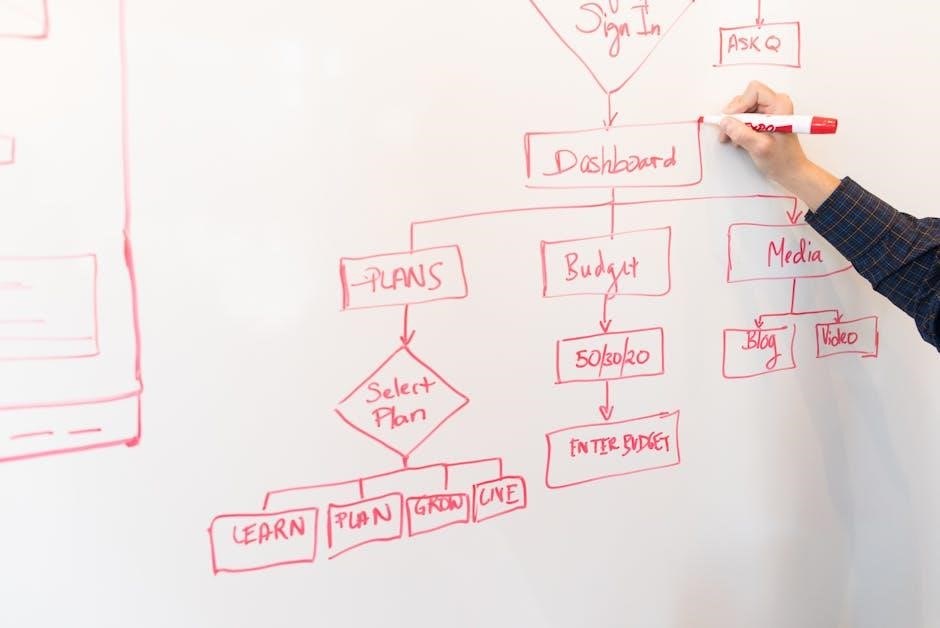

5.1 Adjusting Settings for Optimal Performance

Adjusting settings on the Plantronics W02 ensures optimal performance. Users can customize audio settings, device connections, and firmware updates. The Quick Start Guide provides step-by-step instructions for pairing the headset with mobile devices and managing multiple connections. For advanced customization, refer to the User Manual, which details how to tweak audio quality, adjust volume levels, and enable noise cancellation. Regular firmware updates are essential for maintaining peak performance and accessing new features. By tailoring these settings, users can enhance their overall experience and ensure seamless communication.

5.2 Customizing Audio Settings

Customizing audio settings on the Plantronics W02 enhances sound quality and personal comfort. Users can adjust volume levels, noise cancellation, and equalization presets through the base unit or headset controls. The User Manual provides detailed steps for tweaking audio preferences, ensuring optimal sound clarity. Additionally, the Quick Start Guide outlines how to enable advanced audio features like voice prompts and microphone sensitivity. By tailoring these settings, users can achieve a personalized audio experience, making calls and multimedia playback more enjoyable and professional.

5.3 Updating Firmware and Software

Regular firmware and software updates ensure the Plantronics W02 operates at peak performance. Users can check for updates via the base unit or through the Plantronics software included on the CD. The process involves downloading the latest version, installing it, and restarting the system. The User Manual provides step-by-step guidance for a smooth update experience. It’s crucial to follow these instructions carefully to avoid any interruptions or compatibility issues. For troubleshooting or additional support, refer to the Quick Start Guide or the official Plantronics website for assistance.

Using the Plantronics W02 Manual

The Plantronics W02 manual serves as a comprehensive guide, providing detailed instructions for setup, customization, and troubleshooting. It ensures users can maximize their device’s functionality and performance effectively.

6.1 Navigating the User Manual

The Plantronics W02 manual is structured to guide users through setup, customization, and troubleshooting. It begins with a table of contents for easy navigation. The manual includes detailed sections on pairing devices, adjusting settings, and resolving common issues. Users can find step-by-step instructions for connecting the headset to various devices, such as mobile phones or PCs. Additional resources like the quick start guide provide a concise overview for immediate use. The manual also covers safety information, warranty details, and compliance certificates, ensuring comprehensive understanding and optimal use of the W02 system.

6.2 Quick Start Guide Instructions

The Plantronics W02 Quick Start Guide provides a concise overview for immediate use. It begins with unpacking and connecting the battery, followed by choosing a wearing style; The guide outlines essential features like call management and volume control. Step-by-step instructions help users pair the headset with the base unit and connect to devices. Designed for quick setup, the guide ensures users can start using the W02 system efficiently. For detailed customization and troubleshooting, users are directed to the full manual. This guide is ideal for those seeking to rapidly understand basic functionality and begin using their headset promptly.

6.3 Troubleshooting Common Issues

The Plantronics W02 manual includes a dedicated section for addressing common issues. Users can resolve pairing problems by resetting the headset or base unit. Connectivity drops may require checking Bluetooth settings or device proximity. Audio issues, such as no sound, can often be fixed by adjusting volume levels or ensuring proper headset alignment. The guide also provides steps to address battery-related problems, like charging failures. For persistent issues, the manual recommends performing a factory reset. These troubleshooting tips ensure users can quickly resolve problems and maintain optimal performance. Always refer to the manual for detailed solutions.

Safety Information and Precautions

The Plantronics W02 manual outlines essential safety guidelines, including proper handling, battery care, and compliance with regulatory standards to ensure safe and effective usage.

7.1 Important Safety Guidelines

Adhering to safety guidelines is crucial when using the Plantronics W02. Always read the user manual thoroughly before operation. Avoid exposing the device to extreme temperatures or moisture, as this may damage the components. Handle the headset and base unit with care to prevent physical damage. Ensure proper battery charging and avoid overcharging, as it can lead to battery degradation. Keep the device out of reach of children and follow all regulatory and compliance standards outlined in the manual. Proper usage ensures optimal performance and longevity of the Plantronics W02 system.

7.2 Compliance and Regulatory Information

The Plantronics W02 system complies with regulatory standards to ensure safe and reliable operation. It meets FCC Part 15 requirements and is designed to minimize interference with other devices. The product bears the FCC ID AL8-WO2, confirming its adherence to U.S. regulations. Additionally, it complies with international standards for safety, electromagnetic compatibility, and emissions. Proper usage and installation, as outlined in the manual, ensure compliance with all applicable laws and regulations. Always verify local regulations before use to maintain full compliance and avoid potential legal issues.

7.3 Proper Handling and Storage

Proper handling and storage are essential to maintain the performance and longevity of your Plantronics W02 system. Store the headset and base unit in a cool, dry place, avoiding direct sunlight and extreme temperatures. Use the original packaging or a protective case to prevent physical damage. Keep the devices away from liquids and moisture to avoid corrosion. Clean the headset and base regularly with a soft cloth and avoid harsh chemicals. For extended storage, ensure the battery is charged to at least 50% and update the software to the latest version before storing. Proper care ensures optimal functionality and durability.

Maintenance and Care

Regularly clean the headset and base unit to maintain performance. Store devices in a dry, cool environment and avoid exposure to extreme temperatures or moisture for optimal longevity.

8.1 Cleaning the Headset and Base Unit

Regularly clean the headset and base unit to maintain optimal performance and hygiene. Use a soft, dry cloth to wipe down surfaces, paying attention to areas around the ear cushions and microphone. For stubborn stains, dampen the cloth slightly with water, but avoid excessive moisture. Never use harsh chemicals, alcohol, or abrasive cleaners, as they may damage the finish or electronic components. Avoid submerging any part of the device in water. For the base unit, gently remove dust with a dry cloth and ensure all ports remain dry and free from debris. Cleaning ensures longevity and prevents malfunction.

8.2 Replacing Parts and Accessories

Replacing parts and accessories for the Plantronics W02 is straightforward to ensure optimal performance. Ear cushions, windscreens, and charging bases can be replaced by ordering genuine parts from authorized dealers. To replace, turn off the device, then gently remove the old part and install the new one. For electrical components, such as the battery or base unit connectors, use a screwdriver if necessary. Always refer to the user manual for specific instructions. Ensure all replacements are compatible with your model to maintain functionality and warranty validity. Using original Plantronics parts guarantees quality and reliability.

8.3 Battery Care and Charging Tips

Proper care of the Plantronics W02 battery ensures long-lasting performance. Charge the headset using the provided USB cable and base unit. Avoid overcharging, as it may reduce battery life. Store the battery in a cool, dry place when not in use. If the battery drains quickly, reset it by fully discharging and recharging. Clean contacts with a soft cloth to maintain connectivity. Replace the battery every 2-3 years or when capacity drops significantly. Always use Plantronics-approved chargers to prevent damage. Refer to the user manual for detailed charging instructions and troubleshooting tips.

Advanced Features and Functionality

The Plantronics W02 Series offers advanced features like multi-device connectivity, noise cancellation, and enhanced call management, ensuring a seamless and professional communication experience.

9.1 Multi-Device Connectivity

The Plantronics W02 Series supports multi-device connectivity, allowing users to connect seamlessly to desk phones, computers, and mobile devices. Bluetooth technology enables pairing with mobile phones, while the base unit connects to other devices. This feature ensures flexibility, letting users switch between calls and audio sources effortlessly. Advanced software manages connections, maintaining call quality and reducing interference. With a range of up to 300 feet, users can move freely without losing connection. This functionality enhances productivity, making it ideal for professionals needing to manage multiple communication channels efficiently.

9.2 Call Management Features

The Plantronics W02 Series offers advanced call management features, including call answering, holding, and transferring. Users can easily switch between desk phones and mobile calls. The headset provides voice prompts for status updates and call handling. Mute functionality ensures privacy during conversations, while volume controls allow for personalized audio adjustments. These features streamline communication, reducing distractions and improving efficiency. The system also supports integration with phone systems, enabling seamless call management. With intuitive controls, users can handle multiple calls effortlessly, making it ideal for professionals requiring robust call management capabilities in busy environments.

9.3 Audio Quality Enhancements

The Plantronics W02 Series delivers exceptional audio quality with advanced noise-cancellation technology, ensuring clear voice transmission and reducing background interference. HD audio support provides crisp and natural sound for both calls and multimedia. The headset features a high-quality microphone with enhanced speech clarity, and customizable audio settings allow users to tailor their experience. Additionally, the system includes audio equalization options to optimize sound performance in various environments. These enhancements ensure a professional-grade audio experience, making the W02 Series ideal for environments requiring superior sound quality and reliable communication.

Compatibility and Integration

The Plantronics W02 Series is designed to integrate seamlessly with a variety of devices, including mobile phones, PCs, and phone systems, ensuring universal compatibility and smooth operation.

10.1 Compatibility with Various Devices

The Plantronics W02 Series is engineered to work seamlessly with a wide range of devices, ensuring universal compatibility for enhanced usability. It supports connection to mobile phones, PCs, and desk phones, making it versatile for different work environments. The system’s Bluetooth functionality allows easy pairing with smartphones, while its USB compatibility ensures smooth integration with computers. Additionally, the W02 Series is designed to work with various phone systems, providing a reliable communication solution across multiple platforms. This adaptability makes it an ideal choice for users needing consistent performance across different devices and setups;

10.2 Integration with Phone Systems

The Plantronics W02 Series is designed to integrate effortlessly with various phone systems, ensuring a seamless communication experience. It supports compatibility with desk phones, softphones, and legacy systems, making it a versatile solution for diverse work environments. The system’s advanced features, such as direct connect cables and USB adapters, simplify integration with existing infrastructure. Additionally, the W02 Series works with leading unified communication platforms, enabling users to manage calls efficiently. Its compatibility with both traditional and modern phone systems ensures a smooth transition and optimal performance across different setups.

10.3 Software Compatibility and Requirements

The Plantronics W02 Series is compatible with a range of software platforms, ensuring smooth integration with modern communication tools. It supports popular operating systems like Windows and macOS, making it adaptable to various work environments. The system requires specific software versions for optimal performance, which are typically provided on the included CD or downloadable from the Plantronics website. The Plantronics software enables advanced features such as call management, audio customization, and firmware updates. Ensuring the latest software version is installed guarantees compatibility and enhances the overall user experience, keeping the device up-to-date with evolving communication standards.

The Plantronics W02 Series delivers a robust wireless communication solution, combining advanced features, ease of use, and reliability, making it an excellent choice for professionals seeking high-quality audio performance and seamless connectivity.

11.1 Summary of Key Points

The Plantronics W02 Series is a wireless headset system designed for professional communication, offering advanced features like Bluetooth pairing, multi-device connectivity, and high-quality audio. Its user-friendly design ensures easy setup and customization. The system includes a base unit and headset, with options for additional accessories. The manual provides detailed instructions for installation, pairing, and troubleshooting. Regular maintenance, such as cleaning and battery care, is essential for optimal performance; With its reliability and versatility, the W02 Series is ideal for enhancing productivity in various work environments.

11.2 Final Tips for Optimal Use

For the best experience with your Plantronics W02, ensure regular charging to maintain battery health. Adjust settings to optimize audio quality and connectivity. Keep the headset clean to prevent sound degradation. Store the device properly when not in use. Use genuine accessories for compatibility. Refer to the manual for troubleshooting common issues. Explore advanced features like multi-device pairing to enhance productivity. By following these tips, you can maximize the performance and longevity of your Plantronics W02 wireless headset system.