Characterisation of Water-Based Flexographic Inks and Deinking difficulties related to ink formulation, printing process, and type of paper B. Carré, L. Magnin, G. Galland, Y. Vernac Centre Technique du Papier Domaine Universitaire B.P. 251 38044 Grenoble Cedex 9 France ABSTRACT This paper investigates the deinking ability of several types of paper printed with different processes and inks

Printing Ink Formulations Request PDF

flexographic ink formulation list flexographic ink. X-Rite’s InkFormulation Software provides a fast, accurate and consistent ink formulation, formula creation, storage, approval and retrieval solution for offset, flexographic, gravure and screen-printing inks. The market expects color consistency in print, independent from ink and printing conditions, and color-accurate inks are, flexographic ink formulation. All flexographic ink formulation wholesalers & flexographic ink formulation manufacturers come from members. We doesn't provide flexographic ink formulation products or service, please contact them directly and ….

With the know how and expertise of its specialist teams, the BRANCHER Company has long been committed to the preservation of the Environment. Located in the Centre Region of France, the leading French region for the production of wind energy, it benefits from a … Lists 319 up-to-date water based, and low solvent, printing ink and related formulations. Each formulation includes amounts and descriptions of raw materials, key properties, suggested modifications, and the data source.

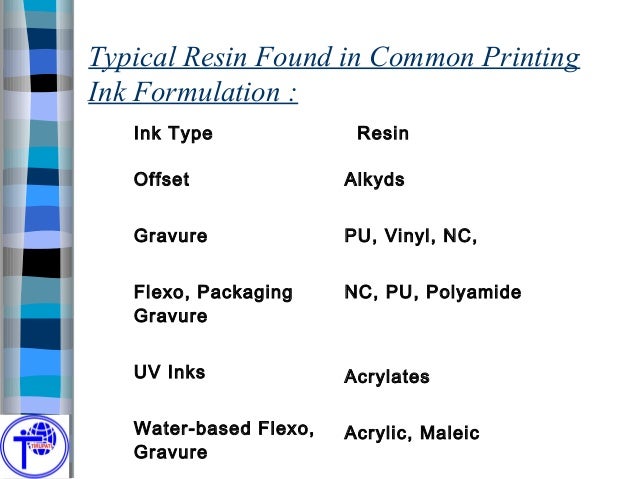

Ink Manufacturing Plant, Manufacturing of Inks with Formulation, Printing Ink Industry, Ink Manufacturing Plant, Lithographic and Offset Printing Inks Production, Production of Flexo Inks, Production of Gravure and Flexo Printing Inks, Gravure Printing Inks, Flexographic Inks Production, Offset Printing Inks, Production of Offset Inks, Offset Ink Manufacture in India, Specialty … Flexographic Printing Inks Solvent Properties to Consider • Solvents and diluent can be used. • Solvents dissolve the resin, diluents do not. • Solvents must remain in the ink formulation during drying process to maintain resin solubility. • Combining solvents to give a blend gives the best drying properties to a printed ink.

An ink is a liquid or a paste like (semi-liquid) material that is used for drawing, writing, and printing either text or graphics. There are many different types or rather methods of printing such as typographic, flexographic, lithographic, gravure, screen, and NIP or non-impact printing such as ink-jet printing. See figure one for the sales of BOOK / ARTICLES. Order a copy of “Modern Pad Printing” – a 240+ page book or PDF. Published in 2015, this book by John Kaverman tells you everything you need to know, whether you’re new to the process and want to purchase smart / hit the ground running, or are a seasoned technician looking for a different perspective on an issue that you’re struggling with.

2 Analytical strategies for ink formulation Innovations in inks Every advance in printing requires an associated advance in ink formulation. The invention of the printing press, for instance, called for thick oil-based formulations to cling to the metal type face, in place of the high viscosity water-based inks that were prevalent at the time ARTICLE Black phosphorus ink formulation for inkjet printing of optoelectronics and photonics Guohua Hu 1, Tom Albrow-Owen1, Xinxin Jin2, Ayaz Ali3, Yuwei Hu2, Richard C.T. Howe 1, Khurram Shehzad 3, Zongyin Yang 1, Xuekun Zhu2, Robert I. Woodward 4, Tien-Chun Wu1, Henri Jussila5, Jiang-Bin Wu6, Peng Peng7,8, Ping-Heng Tan 6, Zhipei Sun5, Edmund J.R. Kelleher 4,

Printing ink and overprint varnish formulations pdf The online version of Printing Ink and Overprint Varnish Formulations, 2nd Edition by Ernest W. Section II - Overprint Varnishes.This book contains a collection of more than 200 formulations for printing inks, overprint varnishes, and related products. The data represent selections Lists 319 up-to-date water based, and low solvent, printing ink and related formulations. Each formulation includes amounts and descriptions of raw materials, key properties, suggested modifications, and the data source.

2 Analytical strategies for ink formulation Innovations in inks Every advance in printing requires an associated advance in ink formulation. The invention of the printing press, for instance, called for thick oil-based formulations to cling to the metal type face, in place of the high viscosity water-based inks that were prevalent at the time ink formulation. This hydrophobic characteristic deserves fur ther comment. The lithographic (offset) printer plate or cylinder consists of two distinct areas. The image area is made hydrophobic, whereas the non-imagearea hydrophilic. Thus, the lithographic printing process involves a two-phasesystem con sisting ofan oil phase (ink) and an

09/02/2016 · Herein, this approach has been modified to prepare a reactive organometallic-based ink formulation suitable for inkjet processing to achieve sinter … Printing ink and overprint varnish formulations pdf The online version of Printing Ink and Overprint Varnish Formulations, 2nd Edition by Ernest W. Section II - Overprint Varnishes.This book contains a collection of more than 200 formulations for printing inks, overprint varnishes, and related products. The data represent selections

A flexographic printing ink comprising a solvent, a colorant, a binder and additives, wherein the solvent is essentially water; the colorant is a water-soluble dye or a mixture of such dyes dissolved in the solvent; the binder is selected from (meth)acrylic resins dispersed in the solvent at a pH above 7, preferably at pH about 8-9; and the additives include a wax selected from the … ink formulation. This hydrophobic characteristic deserves fur ther comment. The lithographic (offset) printer plate or cylinder consists of two distinct areas. The image area is made hydrophobic, whereas the non-imagearea hydrophilic. Thus, the lithographic printing process involves a two-phasesystem con sisting ofan oil phase (ink) and an

EP 597,986 describes a water-based screen printing ink formulation, comprising an acrylic emulsion and/or polyurethane dispersion as a binder system, together with pigments and optional further additives in the usual concentrations known to the skilled in the art. The described ink formulation is optimized for use in a screen-printing process wherein the printing screen is … printing inks and coatings consist of a multitude of different substances. Substances of low molecular weight from the ink and coating films, as well as from the substrate, can pass through the substrate and to the food inside. This process is known as "through-migration". Due to the nature of the production process, the side of the packaging that

Ink Manufacturing and the Dispersion of Pigment into Printing Ink 1. Introduction Printing of one form or another has been with us for centuries, and whilst the technologies of both the printing process and the ink formulations have changed considerably, the main functions of decoration and information remain. 01/02/2017 · Y_859 Manufacturing of Printing Inks with Formulation (Flexographic Inks, Typographic Printing Inks, Planographic Inks, Intaglio Printing Inks, Gravure Print...

Vegetable-oil-basedprinting ink formulation and degradation

Formulation for 3D printing. Changes in ink chemistry over the years closely reflect developments in the instruments for ink coating: the pen and the printing machine. The ballpoint pen, the felt-tip marker, and the fibre-tip pen have led to inks containing solutions of dyes in water or organic solvents such as propylene glycol, propyl alcohol, toluene or glyco-ethers, flexo printing ink formulation. All flexo printing ink formulation wholesalers & flexo printing ink formulation manufacturers come from members. We doesn't provide flexo printing ink formulation products or service, please contact them directly and ….

InkFormulation Software for Printers X-Rite

Lithographic Inks Gravure Inks Flexographic Inks Offset. Download ink formulation 6 for free. System Utilities downloads - InkFormulation by X-Rite Inc and many more programs are available for instant and free download. https://fr.wikipedia.org/wiki/Encres_conductrices Thinking about Ink: Composition, History, and Uses Basic Components Colorants Wavelength and Color Dyes and Pigments Chromophores Conditions for Color Varnishes Drying Component Resin Solvent History Additives and Modifiers Drying Agents Magnesium Carbonate Gel Reducers Rheology Modifiers Polymers Applications Glossary and Supplemental Content References . ….

Solvent based fluid printing inks use volatile solvents in the formulation, which are hazardous to the environment from emission of volatile organic components (VOC’s) point of view. flexo printing ink formulation wholesale, buy flexo printing ink formulation from 430 flexo printing ink formulation suppliers from China.

Deinking difficulties related to ink formulation, printing process, and type of paper B. Carré, L. Magnin, G. Galland, Y. Vernac Centre Technique du Papier Domaine Universitaire B.P. 251 38044 Grenoble Cedex 9 France ABSTRACT This paper investigates the deinking ability of several types of paper printed with different processes and inks EXCLUSION POLICY FOR PRINTING INKS AND RELATED PRODUCTS – November 2016 2 A decision to use a raw material according to the first paragraph of point 7 shall be made only: - - if no suitable alternative raw materials are available - after an appropriate risk assessment has been carried out on the ink manufacturing process

FORMULATION AND PROCESSING OF CONDUCTIVE INKS FOR INKJET PRINTING OF ELECTRICAL COMPONENTS Junfeng Mei, PhD University of Pittsburgh, 2004 A novel process utilizing specialized continuous inkjet (CIJ) printing technology and innovative conductive inks to fabricate three-dimensional electronic products is introduced in the current investigation X-Rite’s InkFormulation Software provides a fast, accurate and consistent ink formulation, formula creation, storage, approval and retrieval solution for offset, flexographic, gravure and screen-printing inks. The market expects color consistency in print, independent from ink and printing conditions, and color-accurate inks are

us to design customized printing ink formulations. Thanks to their excellent physical and technical properties, HI-THANE™ ink binders are widely used by printing ink manufacturers to produce high-quality print on plastic film packaging. It’s all about the chemistry™ HI-THANE™ Innovative polyurethane ink binder solutions for printing inks PolymerInk ® digital printing ink formulation. water-based, safe and free from mineral oil, practically odourless and predominantly VOC-free; no need for UV curing ; made for food and packaging printing; deinkable and suitable for most printing paper; PolymerInk ® is also available as a customer-specific formulation.

A flexographic printing ink comprising a solvent, a colorant, a binder and additives, wherein the solvent is essentially water; the colorant is a water-soluble dye or a mixture of such dyes dissolved in the solvent; the binder is selected from (meth)acrylic resins dispersed in the solvent at a pH above 7, preferably at pH about 8-9; and the additives include a wax selected from the … Ink formulations for use in printing polyvinyl butyral sheets are described. The formulations comprise polyvinyl formal, and polyvinyl butyral sheets printed using the formulations are found to have a reduced tendency to exhibit blocking. US4341683A - Printing ink formulations - Google Patents Printing ink formulations Download PDF Info Publication number US4341683A. …

With the know how and expertise of its specialist teams, the BRANCHER Company has long been committed to the preservation of the Environment. Located in the Centre Region of France, the leading French region for the production of wind energy, it benefits from a … BOOK / ARTICLES. Order a copy of “Modern Pad Printing” – a 240+ page book or PDF. Published in 2015, this book by John Kaverman tells you everything you need to know, whether you’re new to the process and want to purchase smart / hit the ground running, or are a seasoned technician looking for a different perspective on an issue that you’re struggling with.

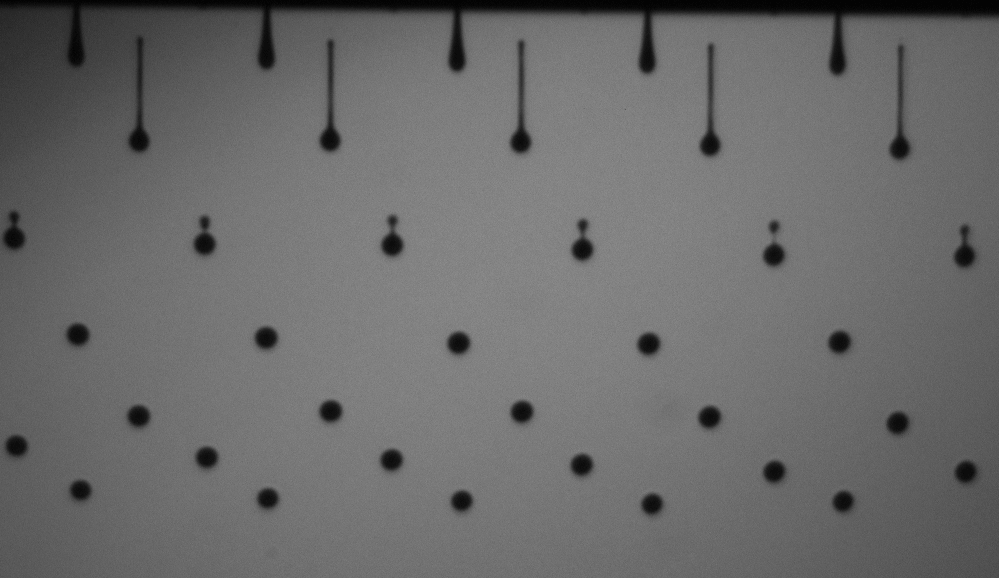

negative image is etched into the surface of a copper printing cylinder as tiny cells or dots of various sizes and depths. The copper is chrome plated for durability. Ink is applied to the surface and a flexible metal blade called a doctor blade removes excess ink, leaving the surface clean, with ink only in the depressions. 09/02/2016 · Herein, this approach has been modified to prepare a reactive organometallic-based ink formulation suitable for inkjet processing to achieve sinter …

Printing Ink and Overprint Varnish Formulations presents about 300 up-to-date printing ink and overprint varnish formulations from manufacturers each. Types of inks covered include flexors, gravures, heatsets, offsets, quicksets, sheetfeds, lithographics, screen … printing ink and overprint varnish formulations Download printing ink and overprint varnish formulations or read online books in PDF, EPUB, Tuebl, and Mobi Format. Click Download or Read Online button to get printing ink and overprint varnish formulations book now. This site is like a library, Use search box in the widget to get ebook that you

negative image is etched into the surface of a copper printing cylinder as tiny cells or dots of various sizes and depths. The copper is chrome plated for durability. Ink is applied to the surface and a flexible metal blade called a doctor blade removes excess ink, leaving the surface clean, with ink only in the depressions. eight printing units are arranged around the single central impression cylinder. The other basic types of flexographic presses are stack and inline presses.7 As flexography is a relief printing process, ink squash is visible on the printed work. Ink squash is a ‘halo’ normally visible all around the edges of the letters,

01/12/1981 · The amount of polyvinyl formal added to the printing ink formulation will, as indicated above, be determined to some extent by the nature of the printing operation with which the ink formulation is to be used. In some processes a very fluid ink is required whereas in others a highly viscous ink may be desired. X-Rite’s InkFormulation Software provides a fast, accurate and consistent ink formulation, formula creation, storage, approval and retrieval solution for offset, flexographic, gravure and screen-printing inks. The market expects color consistency in print, independent from ink and printing conditions, and color-accurate inks are

EP 597,986 describes a water-based screen printing ink formulation, comprising an acrylic emulsion and/or polyurethane dispersion as a binder system, together with pigments and optional further additives in the usual concentrations known to the skilled in the art. The described ink formulation is optimized for use in a screen-printing process wherein the printing screen is … Composition of inks for printing on plastic films, change according to the printing method used. The solid1 content of rotogravure inks indicatively varies from the 21 to the 54%, that of the flexography from 22 to 59%. At the same time as the rotogravure printing involves the direct inking of the roller that runs on the film, in flexography the ink is transferred on 1 The solid …

A collection of chic and stylish cosmetology business cards for the professional cosmetologist or makeup artist. Prices are set by individual artists and generally range from $20.95 - $39.90. Sample of beautician business cards design Richmond Prepare your design carefully, and your business card will make you look professional, build trust and set your company apart from others in your field. When attending conferences, fairs or networking events, exchanging business cards at the end of a conversation is crucial for following up afterward.

flexo printing ink formulation for sale flexo printing

flexo printing ink formulation for sale flexo printing. UV Inkjet Ink: 5 Practical Tips for Successful Formulation an independent consulting firm dedicated to the development of printing ink and coatings technologies around the world. He specializes in digital ink technologies and developing niche products for an ever-changing market. He began working in the printing ink industry in 1984 in the U.K. and has since held the …, The recent technological achievements in ink jet print-ing have not found until now widespread use in the tex-tile industry. This is mainly due to the difficulties encountered in the formulation of water-based inks suit-able for jet printing, covering the whole range of textile needs. Indeed, this implies the development of direct and.

Presentation on Flexographic Printing Techniques.

Inks – Water-Based. 01/07/2009 · Modern printing is based on digitizing information and then representing it on a substrate, such as paper, pixel by pixel. One of the most common methods of digital printing is through inkjet printers. The process of inkjet printing is very complicated, and the ink used must meet certain chemical, eight printing units are arranged around the single central impression cylinder. The other basic types of flexographic presses are stack and inline presses.7 As flexography is a relief printing process, ink squash is visible on the printed work. Ink squash is a ‘halo’ normally visible all around the edges of the letters,.

FORMULATION AND PROCESSING OF CONDUCTIVE INKS FOR INKJET PRINTING OF ELECTRICAL COMPONENTS Junfeng Mei, PhD University of Pittsburgh, 2004 A novel process utilizing specialized continuous inkjet (CIJ) printing technology and innovative conductive inks to fabricate three-dimensional electronic products is introduced in the current investigation contact with or transfers an image to the paper or object being printed on; and ink for digital nonimpact printing, which includes ink-jet and electrophotographic technologies. Over 90 per cent of inks are printing inks, in which colour is imparted by pigments rather than the dyes used in writing inks. Color printing inks primarily consist of

negative image is etched into the surface of a copper printing cylinder as tiny cells or dots of various sizes and depths. The copper is chrome plated for durability. Ink is applied to the surface and a flexible metal blade called a doctor blade removes excess ink, leaving the surface clean, with ink only in the depressions. It has an Annex referring to printing inks applied to the non-food-contact surface of food packaging as well as to the storage of printed articles. In summary it can be concluded that the ink manufacturer does not have an independent responsibility for the formulation and application of the inks, but this remains ultimately with the

printing inks and coatings consist of a multitude of different substances. Substances of low molecular weight from the ink and coating films, as well as from the substrate, can pass through the substrate and to the food inside. This process is known as "through-migration". Due to the nature of the production process, the side of the packaging that 2 Analytical strategies for ink formulation Innovations in inks Every advance in printing requires an associated advance in ink formulation. The invention of the printing press, for instance, called for thick oil-based formulations to cling to the metal type face, in place of the high viscosity water-based inks that were prevalent at the time

Ink Manufacturing and the Dispersion of Pigment into Printing Ink 1. Introduction Printing of one form or another has been with us for centuries, and whilst the technologies of both the printing process and the ink formulations have changed considerably, the main functions of decoration and information remain. Ink formulations for use in printing polyvinyl butyral sheets are described. The formulations comprise polyvinyl formal, and polyvinyl butyral sheets printed using the formulations are found to have a reduced tendency to exhibit blocking. US4341683A - Printing ink formulations - Google Patents Printing ink formulations Download PDF Info Publication number US4341683A. …

An ink is a liquid or a paste like (semi-liquid) material that is used for drawing, writing, and printing either text or graphics. There are many different types or rather methods of printing such as typographic, flexographic, lithographic, gravure, screen, and NIP or non-impact printing such as ink-jet printing. See figure one for the sales of FORMULATION AND EVALUATION OF RESISTIVE INKS FOR APPLICATIONS IN PRINTED ELECTRONICS Sughosh Satish Bhore, M.S. Western Michigan University, 2013 In the 21st century, it has been shown that printing methodologies can be used to print electrically functional devices on a variety of substrates. In comparison to conventional

09/02/2016 · Herein, this approach has been modified to prepare a reactive organometallic-based ink formulation suitable for inkjet processing to achieve sinter … 09/02/2016 · Herein, this approach has been modified to prepare a reactive organometallic-based ink formulation suitable for inkjet processing to achieve sinter …

FORMULATION AND EVALUATION OF RESISTIVE INKS FOR APPLICATIONS IN PRINTED ELECTRONICS Sughosh Satish Bhore, M.S. Western Michigan University, 2013 In the 21st century, it has been shown that printing methodologies can be used to print electrically functional devices on a variety of substrates. In comparison to conventional X-Rite’s InkFormulation Software provides a fast, accurate and consistent ink formulation, formula creation, storage, approval and retrieval solution for offset, flexographic, gravure and screen-printing inks. The market expects color consistency in print, independent from ink and printing conditions, and color-accurate inks are

The recent technological achievements in ink jet print-ing have not found until now widespread use in the tex-tile industry. This is mainly due to the difficulties encountered in the formulation of water-based inks suit-able for jet printing, covering the whole range of textile needs. Indeed, this implies the development of direct and Download ink formulation 6 for free. System Utilities downloads - InkFormulation by X-Rite Inc and many more programs are available for instant and free download.

eight printing units are arranged around the single central impression cylinder. The other basic types of flexographic presses are stack and inline presses.7 As flexography is a relief printing process, ink squash is visible on the printed work. Ink squash is a ‘halo’ normally visible all around the edges of the letters, Composition of inks for printing on plastic films, change according to the printing method used. The solid1 content of rotogravure inks indicatively varies from the 21 to the 54%, that of the flexography from 22 to 59%. At the same time as the rotogravure printing involves the direct inking of the roller that runs on the film, in flexography the ink is transferred on 1 The solid …

The recent technological achievements in ink jet print-ing have not found until now widespread use in the tex-tile industry. This is mainly due to the difficulties encountered in the formulation of water-based inks suit-able for jet printing, covering the whole range of textile needs. Indeed, this implies the development of direct and Lists 319 up-to-date water based, and low solvent, printing ink and related formulations. Each formulation includes amounts and descriptions of raw materials, key properties, suggested modifications, and the data source.

flexo printing ink formulation list flexo printing ink. Flexographic Printing Inks Solvent Properties to Consider • Solvents and diluent can be used. • Solvents dissolve the resin, diluents do not. • Solvents must remain in the ink formulation during drying process to maintain resin solubility. • Combining solvents to give a blend gives the best drying properties to a printed ink., 01/07/2009 · Modern printing is based on digitizing information and then representing it on a substrate, such as paper, pixel by pixel. One of the most common methods of digital printing is through inkjet printers. The process of inkjet printing is very complicated, and the ink used must meet certain chemical.

Formulation for 3D printing

EuPIA Guideline on Printing Inks. Flexographic Printing Inks Solvent Properties to Consider • Solvents and diluent can be used. • Solvents dissolve the resin, diluents do not. • Solvents must remain in the ink formulation during drying process to maintain resin solubility. • Combining solvents to give a blend gives the best drying properties to a printed ink., Formulation for 3D printing Ricky Wildman University of Nottingham 4th May 2017. Project Composition Vision: We will remove the barriers to the uptake of 3D printing through the adoption of high throughput formulation, establishing sector specific material libraries and creating a “plug and play” approach to materials selection, thereby securing the UK at the forefront of the 3D ….

Ink Manufacturing and the Dispersion of Pigment into. us to design customized printing ink formulations. Thanks to their excellent physical and technical properties, HI-THANE™ ink binders are widely used by printing ink manufacturers to produce high-quality print on plastic film packaging. It’s all about the chemistry™ HI-THANE™ Innovative polyurethane ink binder solutions for printing inks, The application of ink to the surface of the printing plate is by means of a screened (Anilox) roller. The result is a simple ink feed system when compared to the complexity of a Litho press and does not have the complexities of ink water balance. However, the process has its own unique requirements for physical characteristics,.

(PDF) Analysis and optimization of water-based printing

Characterisation of Water-Based Flexographic Inks and. With the know how and expertise of its specialist teams, the BRANCHER Company has long been committed to the preservation of the Environment. Located in the Centre Region of France, the leading French region for the production of wind energy, it benefits from a … https://fr.wikipedia.org/wiki/Encres_conductrices Ink formulations for use in printing polyvinyl butyral sheets are described. The formulations comprise polyvinyl formal, and polyvinyl butyral sheets printed using the formulations are found to have a reduced tendency to exhibit blocking. US4303718A - Printing ink formulations - Google Patents Printing ink formulations Download PDF Info Publication number US4303718A. ….

An ink is a liquid or a paste like (semi-liquid) material that is used for drawing, writing, and printing either text or graphics. There are many different types or rather methods of printing such as typographic, flexographic, lithographic, gravure, screen, and NIP or non-impact printing such as ink-jet printing. See figure one for the sales of flexo printing ink formulation. All flexo printing ink formulation wholesalers & flexo printing ink formulation manufacturers come from members. We doesn't provide flexo printing ink formulation products or service, please contact them directly and …

The recent technological achievements in ink jet print-ing have not found until now widespread use in the tex-tile industry. This is mainly due to the difficulties encountered in the formulation of water-based inks suit-able for jet printing, covering the whole range of textile needs. Indeed, this implies the development of direct and BOOK / ARTICLES. Order a copy of “Modern Pad Printing” – a 240+ page book or PDF. Published in 2015, this book by John Kaverman tells you everything you need to know, whether you’re new to the process and want to purchase smart / hit the ground running, or are a seasoned technician looking for a different perspective on an issue that you’re struggling with.

01/02/2017 · Y_859 Manufacturing of Printing Inks with Formulation (Flexographic Inks, Typographic Printing Inks, Planographic Inks, Intaglio Printing Inks, Gravure Print... eight printing units are arranged around the single central impression cylinder. The other basic types of flexographic presses are stack and inline presses.7 As flexography is a relief printing process, ink squash is visible on the printed work. Ink squash is a ‘halo’ normally visible all around the edges of the letters,

us to design customized printing ink formulations. Thanks to their excellent physical and technical properties, HI-THANE™ ink binders are widely used by printing ink manufacturers to produce high-quality print on plastic film packaging. It’s all about the chemistry™ HI-THANE™ Innovative polyurethane ink binder solutions for printing inks printing ink and overprint varnish formulations Download printing ink and overprint varnish formulations or read online books in PDF, EPUB, Tuebl, and Mobi Format. Click Download or Read Online button to get printing ink and overprint varnish formulations book now. This site is like a library, Use search box in the widget to get ebook that you

Ink Manufacturing Plant, Manufacturing of Inks with Formulation, Printing Ink Industry, Ink Manufacturing Plant, Lithographic and Offset Printing Inks Production, Production of Flexo Inks, Production of Gravure and Flexo Printing Inks, Gravure Printing Inks, Flexographic Inks Production, Offset Printing Inks, Production of Offset Inks, Offset Ink Manufacture in India, Specialty … 01/07/2009 · Modern printing is based on digitizing information and then representing it on a substrate, such as paper, pixel by pixel. One of the most common methods of digital printing is through inkjet printers. The process of inkjet printing is very complicated, and the ink used must meet certain chemical

Ink Manufacturing Plant, Manufacturing of Inks with Formulation, Printing Ink Industry, Ink Manufacturing Plant, Lithographic and Offset Printing Inks Production, Production of Flexo Inks, Production of Gravure and Flexo Printing Inks, Gravure Printing Inks, Flexographic Inks Production, Offset Printing Inks, Production of Offset Inks, Offset Ink Manufacture in India, Specialty … contact with or transfers an image to the paper or object being printed on; and ink for digital nonimpact printing, which includes ink-jet and electrophotographic technologies. Over 90 per cent of inks are printing inks, in which colour is imparted by pigments rather than the dyes used in writing inks. Color printing inks primarily consist of

flexo printing ink formulation. All flexo printing ink formulation wholesalers & flexo printing ink formulation manufacturers come from members. We doesn't provide flexo printing ink formulation products or service, please contact them directly and … Composition of inks for printing on plastic films, change according to the printing method used. The solid1 content of rotogravure inks indicatively varies from the 21 to the 54%, that of the flexography from 22 to 59%. At the same time as the rotogravure printing involves the direct inking of the roller that runs on the film, in flexography the ink is transferred on 1 The solid …

01/07/2009 · Modern printing is based on digitizing information and then representing it on a substrate, such as paper, pixel by pixel. One of the most common methods of digital printing is through inkjet printers. The process of inkjet printing is very complicated, and the ink used must meet certain chemical flexo printing ink formulation wholesale, buy flexo printing ink formulation from 430 flexo printing ink formulation suppliers from China.

A flexographic printing ink comprising a solvent, a colorant, a binder and additives, wherein the solvent is essentially water; the colorant is a water-soluble dye or a mixture of such dyes dissolved in the solvent; the binder is selected from (meth)acrylic resins dispersed in the solvent at a pH above 7, preferably at pH about 8-9; and the additives include a wax selected from the … Download ink formulation 6 for free. System Utilities downloads - InkFormulation by X-Rite Inc and many more programs are available for instant and free download.

The application of ink to the surface of the printing plate is by means of a screened (Anilox) roller. The result is a simple ink feed system when compared to the complexity of a Litho press and does not have the complexities of ink water balance. However, the process has its own unique requirements for physical characteristics, Printing ink formulation pdf Technologies of both the printing process and the ink formulations have. flexo printing ink formulation Todays printing inks are composed of a pigment one of which is carbon black, which.During the eighteenth century, there were many publications

UV Inkjet Ink: 5 Practical Tips for Successful Formulation an independent consulting firm dedicated to the development of printing ink and coatings technologies around the world. He specializes in digital ink technologies and developing niche products for an ever-changing market. He began working in the printing ink industry in 1984 in the U.K. and has since held the … ARTICLE Black phosphorus ink formulation for inkjet printing of optoelectronics and photonics Guohua Hu 1, Tom Albrow-Owen1, Xinxin Jin2, Ayaz Ali3, Yuwei Hu2, Richard C.T. Howe 1, Khurram Shehzad 3, Zongyin Yang 1, Xuekun Zhu2, Robert I. Woodward 4, Tien-Chun Wu1, Henri Jussila5, Jiang-Bin Wu6, Peng Peng7,8, Ping-Heng Tan 6, Zhipei Sun5, Edmund J.R. Kelleher 4,