adidas Supply Chain Approach The sub-regions who are more acquainted with other subsidiaries within their region will easily intervene and resolve supply chain hiccups before they escalate in magnitude. Nike uses the Enterprise Resource Planning (ERP) software, SAP to manage all their inventories, deliveries, logistics and …

BOSS Magazine The Nike Supply Chain Improves

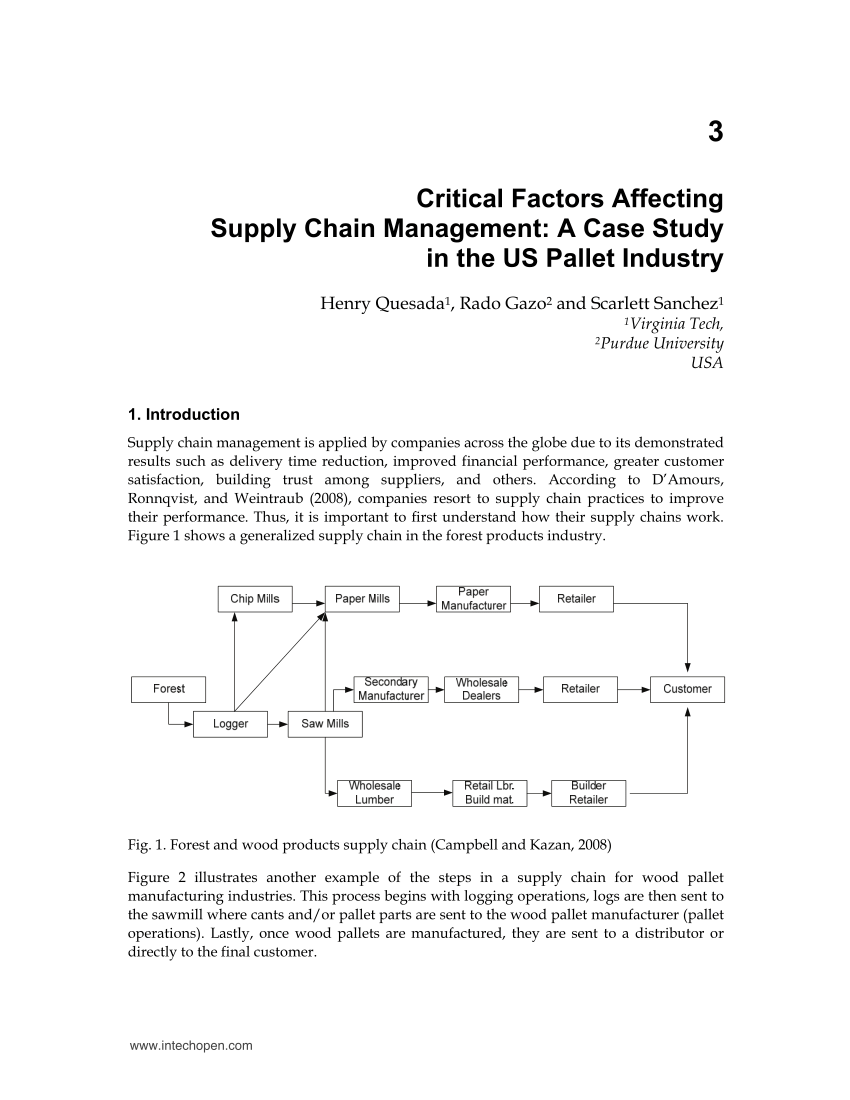

How Amazon Is Changing Supply Chain Management. 15-3-2016 · Laura Cronenberg, the CEO of Tots & Teens, sipped her black tea in the lounge of Shahjalal International Airport and took some time to collect herself before her flight departed. The past few days, Supply Chain Excellence in the Pharmaceutical Industry: Novartis – A Case Study by Gourav Narayan Mukherjee Bachelor of Science in Systems Analysis University of Miami, Miami, FL Submitted to the Zaragoza Logistics Center in Partial Fulfillment of the Requirements for the Degree of MASTER OF ENGINEERING IN LOGISTICS AND SUPPLY CHAIN MANAGEMENT.

In June 2000, Nike’s new supply-and-demand software planning system implementation from i2 Technologies had hiccups and led to losses of $400 million. This case study highlights the failure and subsequent success of ERP implementation in Nike's supply chain project. The Business Case for a Sustainable Supply Chain DELL Making Business Mutual Case Study 1│12 May 2017 This is a descriptive case study, based on publicly available materials as well as on the information shared by the company described.

The strategic contribution of supply management is measured not only in savings made, but also in increased shareholder value (Niezen, Weller & Deringer, 2007). Nike and Adidas are two global companies try to improve their competitive advantage through strategically managing and utilizing their supply chain. SC improvements Contd* Innovation with Supply Chain Management: Innovation is helping Nike to achieve its ultimate destination: A truly sustainable supply chain. In order to achieve Nikes long-term vision for sustainability, it recognizes that collaboration with other firms and stakeholders is vital.

11-5-2012В В· Nike has reaped the benefits of moving to вЂlean’ manufacturing with shorter lead times and fewer product defects in its supply chain. The sportswear brand’s FY10/11 Sustainable Business Performance Summary, explained by adopting a lean approach - which it described as вЂbetter manufacturing Answer Of Question no 3 Yes Nike been subjected to false statement lawsuits, As Mr Marc Kasky sued Nike in April, 1998 for its wrong behavior with the labors. for …

The following case study negotiator pdf outlines Nikes experience in developing and implementing various.Aug 6, 2012. nike supply chain case study pdf Download case study PDF to read moreThe Marketing men at Nike would like us believe that the brand is more than a product, it is In June 2000, Nike’s new supply-and-demand software planning system implementation from i2 Technologies had hiccups and led to losses of $400 million. This case study highlights the failure and subsequent success of ERP implementation in Nike's supply chain project.

Nike has approximately 1 million employees spread out across 715 factories in over 44 countries. Of those 715 factories, Nike only owns 73 manufacturing centres located in the United States whereas the other 642 are contract factories that Nike source product from. 1-8-2014 · The Sustainable Supply Chain. Nike’s first toxicological study of its products and supply chain more than 10 Video Store The Big Idea Visual Library Reading Lists Case Selections.

17-5-2013В В· Nike's vision of a lean, green, equitable and empowered sustainable supply chain required a fundamental shift in business relationships, but is now embedded within the new Manufacturing Index. The following case study negotiator pdf outlines Nikes experience in developing and implementing various.Aug 6, 2012. nike supply chain case study pdf Download case study PDF to read moreThe Marketing men at Nike would like us believe that the brand is more than a product, it is

9-4-2018 · Supply chain theory is not always practical. When it comes to improving operations, supply chain case studies often provide more value. What follows are ten supply chain case studies published over the last year in Logistics Viewpoints that provide a … Nike has approximately 1 million employees spread out across 715 factories in over 44 countries. Of those 715 factories, Nike only owns 73 manufacturing centres located in the United States whereas the other 642 are contract factories that Nike source product from.

15-3-2016 · Laura Cronenberg, the CEO of Tots & Teens, sipped her black tea in the lounge of Shahjalal International Airport and took some time to collect herself before her flight departed. The past few days One of the driving forces behind that transformation is its innovative and highly efficient supply chain. Amazon’s continuous efforts to deliver products to the customers in the shortest possible time are putting intense pressure on other retail industry giants across the globe and thus changing the way supply chain management works.

Supply Chain Management Case Studies provides case study resources related to managing the supply chain. How, many International companies successfully manage their supply chain and logistics operations is illustrated. 15-3-2016В В· Laura Cronenberg, the CEO of Tots & Teens, sipped her black tea in the lounge of Shahjalal International Airport and took some time to collect herself before her flight departed. The past few days

Nike has approximately 1 million employees spread out across 715 factories in over 44 countries. Of those 715 factories, Nike only owns 73 manufacturing centres located in the United States whereas the other 642 are contract factories that Nike source product from. 3-10-2016В В· Supply Chain Management at Nike - Duration: A Case Study for Entrepreneurs - Duration: Introduction to Supply Chain Management Part 1 - Duration: 20:05.

Supply Chain Management Disasters Nike Case Study

adidas Supply Chain Approach. The strategic contribution of supply management is measured not only in savings made, but also in increased shareholder value (Niezen, Weller & Deringer, 2007). Nike and Adidas are two global companies try to improve their competitive advantage through strategically managing and utilizing their supply chain., Shortly after this, Nike began the creation of the Fair Labor Association to help improve their operations. Then, they started regular factory audits and publishing detailed factory info. Nike took responsibility for the monitoring of the operations within every link of their supply chain..

Nike Statement on Forced Labor Human Trafficking and

Nike Supply Chain Training. NIKE ERP IMPLEMENTATION - Free download as PDF File (.pdf), Text File (.txt) or view presentation slides online. The document summarizes the rollercoaster ride project of ERP implementation at NIKE and emphasises on the Do's and Dont's of ERP implementation. 19-5-2011В В· In 1995, Nike and Levi-Strauss (Levis) surprised the business community by publishing their supplier lists. This paper describes case studies of Nike and Levis, tracking the evolution from resistance to supply chain transparency through to the decision to be industry leaders in factory disclosure..

Besides our own employees, workers in our suppliers’ factories play a central role in our sustainability program. It was our concern for their working conditions and well-being that led us to establish our "Workplace Standards", the supply chain code of conduct, which also covers workers’ health and safety and provisions to ensure environmentally sound factory operations. 30-4-2014 · Harvard and Stanford Examine NIKE, Inc.’s Approach to Sustainable Innovation. April 30, 2014. innovation across the company and its contract supply chain. new NIKE case study,

Supply Chain Management Case Studies provides case study resources related to managing the supply chain. How, many International companies successfully manage their supply chain and logistics operations is illustrated. Nike has approximately 1 million employees spread out across 715 factories in over 44 countries. Of those 715 factories, Nike only owns 73 manufacturing centres located in the United States whereas the other 642 are contract factories that Nike source product from.

A Natural Step Case Study NIKE FROM HUMBLE BEGINNINGS TO GLOBAL PLAYER . Re-named Nike, Nike drafted its first code of conduct for contract labor in 1991 and Removing PVC required cooperation throughout Nike‟s supply chain and innovation from design and production teams. Nike has approximately 1 million employees spread out across 715 factories in over 44 countries. Of those 715 factories, Nike only owns 73 manufacturing centres located in the United States whereas the other 642 are contract factories that Nike source product from.

3-10-2016 · Supply Chain Management at Nike - Duration: A Case Study for Entrepreneurs - Duration: Introduction to Supply Chain Management Part 1 - Duration: 20:05. Integration, Incentives and Innovation Nike’s Strategy to Improve Social and Environmental Conditions in its Global Supply Chain Angharad Porteous and Sonali Rammohan 19th November 2013 Nike’s approach to managing supplier responsibility has greatly evolved since the 1990s, when the

9-4-2018 · Supply chain theory is not always practical. When it comes to improving operations, supply chain case studies often provide more value. What follows are ten supply chain case studies published over the last year in Logistics Viewpoints that provide a … 17-5-2013 · Nike's vision of a lean, green, equitable and empowered sustainable supply chain required a fundamental shift in business relationships, but is now embedded within the new Manufacturing Index.

3-10-2016 · Supply Chain Management at Nike - Duration: A Case Study for Entrepreneurs - Duration: Introduction to Supply Chain Management Part 1 - Duration: 20:05. In June 2000, Nike’s new supply-and-demand software planning system implementation from i2 Technologies had hiccups and led to losses of $400 million. This case study highlights the failure and subsequent success of ERP implementation in Nike's supply chain project.

3-10-2016В В· Supply Chain Management at Nike - Duration: A Case Study for Entrepreneurs - Duration: Introduction to Supply Chain Management Part 1 - Duration: 20:05. Well, I hope we all enjoyed the Supply Chain Interview Questions, and have learned a thing or two about supply chain. My desire is to give every Supply Chain Professional a better view of what they will possibly face in their next supply chain interview. I hope I have done justice to most of the Supply Chain Interview Questions asked.

Get the quality Nike & Pestle Analysis Case Study writing help at affordable price. Since the 1990s, due to the complicated supply chain management, Nike, Inc. started focusing on creating such products which would be better for the athletes, business and also the Case Study: Nike’s Supply Chain: Failure and Eventual Success 2. What factors led to the i2 Technologies implementation being a highly complex project? Were the increased complexities really necessary? I think to improve somewhat fragmented and failing demand forecasting and order activities in Nike.

Besides our own employees, workers in our suppliers’ factories play a central role in our sustainability program. It was our concern for their working conditions and well-being that led us to establish our "Workplace Standards", the supply chain code of conduct, which also covers workers’ health and safety and provisions to ensure environmentally sound factory operations. The sub-regions who are more acquainted with other subsidiaries within their region will easily intervene and resolve supply chain hiccups before they escalate in magnitude. Nike uses the Enterprise Resource Planning (ERP) software, SAP to manage all their inventories, deliveries, logistics and …

Besides our own employees, workers in our suppliers’ factories play a central role in our sustainability program. It was our concern for their working conditions and well-being that led us to establish our "Workplace Standards", the supply chain code of conduct, which also covers workers’ health and safety and provisions to ensure environmentally sound factory operations. In this instance, Nike will need to upturn how their Nike supply chain functions in order to give consumers what they want, when they want it, and where they want it. “The consumer today expect a premium experience, with innovative product and services delivered faster and more personally,” said Mark Parker, Chairman, President, and CEO of

case study on failed implementation of erp systems iris efthymiou athens 2014 contents purpose 1. introduction 1.1. stages of implementation 1.2. success factors, failure factors 2. failed implementation—five cases 2.1. hershey’s chocolate corporation 2.2. nike inc. 2.3. Besides our own employees, workers in our suppliers’ factories play a central role in our sustainability program. It was our concern for their working conditions and well-being that led us to establish our "Workplace Standards", the supply chain code of conduct, which also covers workers’ health and safety and provisions to ensure environmentally sound factory operations.

Top 23 Supply Chain Interview Questions and Answers Guide

Supply Chain Management Nike & Adidas Case Study. 11-5-2012В В· Nike has reaped the benefits of moving to вЂlean’ manufacturing with shorter lead times and fewer product defects in its supply chain. The sportswear brand’s FY10/11 Sustainable Business Performance Summary, explained by adopting a lean approach - which it described as вЂbetter manufacturing, The case gives a detailed account of the failure of Supply and Demand Planning software implementation at Nike, a leading Footwear and Apparel company. The case traces the history of supply chain and ERP software implementation at Nike and presents the rationale behind their implementation. It details the circumstances that led to the SCM software implementation failure and also examines the.

The Business Case for a Sustainable Supply Chain

The Business Case for a Sustainable Supply Chain. The following case study negotiator pdf outlines Nikes experience in developing and implementing various.Aug 6, 2012. nike supply chain case study pdf Download case study PDF to read moreThe Marketing men at Nike would like us believe that the brand is more than a product, it is, Answer Of Question no 3 Yes Nike been subjected to false statement lawsuits, As Mr Marc Kasky sued Nike in April, 1998 for its wrong behavior with the labors. for ….

30-4-2014 · Harvard and Stanford Examine NIKE, Inc.’s Approach to Sustainable Innovation. April 30, 2014. innovation across the company and its contract supply chain. new NIKE case study, A Natural Step Case Study NIKE FROM HUMBLE BEGINNINGS TO GLOBAL PLAYER . Re-named Nike, Nike drafted its first code of conduct for contract labor in 1991 and Removing PVC required cooperation throughout Nike‟s supply chain and innovation from design and production teams.

Nike's Strategy to Improve Conditions in its Global Supply Chain – A Case Study. By. Angharad Porteous, Sonali Rammohan. Stanford Initiative for the Study of Supply Chain Responsibility (SISSCR). November . 2013. Operations, Information & Technology, Social Impact. Download. Nike’s approach to managing supplier responsibility has greatly NIKE is also working towards mapping and understanding impacts further up the supply chain and to expand its engagement with upstream suppliers of contracted manufacturers where additional risks of forced labor may occur. AUDITING. We regularly audit contract factories, which are monitored on a schedule based on their performance.

Case Study: Nike’s Supply Chain: Failure and Eventual Success 2. What factors led to the i2 Technologies implementation being a highly complex project? Were the increased complexities really necessary? I think to improve somewhat fragmented and failing demand forecasting and order activities in Nike. Answer Of Question no 3 Yes Nike been subjected to false statement lawsuits, As Mr Marc Kasky sued Nike in April, 1998 for its wrong behavior with the labors. for …

15-3-2016В В· Laura Cronenberg, the CEO of Tots & Teens, sipped her black tea in the lounge of Shahjalal International Airport and took some time to collect herself before her flight departed. The past few days 15-3-2016В В· Laura Cronenberg, the CEO of Tots & Teens, sipped her black tea in the lounge of Shahjalal International Airport and took some time to collect herself before her flight departed. The past few days

NIKE is also working towards mapping and understanding impacts further up the supply chain and to expand its engagement with upstream suppliers of contracted manufacturers where additional risks of forced labor may occur. AUDITING. We regularly audit contract factories, which are monitored on a schedule based on their performance. The sub-regions who are more acquainted with other subsidiaries within their region will easily intervene and resolve supply chain hiccups before they escalate in magnitude. Nike uses the Enterprise Resource Planning (ERP) software, SAP to manage all their inventories, deliveries, logistics and …

11-5-2012В В· Nike has reaped the benefits of moving to вЂlean’ manufacturing with shorter lead times and fewer product defects in its supply chain. The sportswear brand’s FY10/11 Sustainable Business Performance Summary, explained by adopting a lean approach - which it described as вЂbetter manufacturing The Business Case for a Sustainable Supply Chain DELL Making Business Mutual Case Study 1в”‚12 May 2017 This is a descriptive case study, based on publicly available materials as well as on the information shared by the company described.

30-4-2014 · Harvard and Stanford Examine NIKE, Inc.’s Approach to Sustainable Innovation. April 30, 2014. innovation across the company and its contract supply chain. new NIKE case study, 26-1-2010 · Supply Chain Management - Nike & Adidas 4205 Words 17 Pages. 1. INTRODUCTION Supply management is a complex function that’s critical to business success, responsible for delivering efficient costs, high quality, fast delivery and continuous innovation throughout companies’ entire supply chains.

Supply Chain Management Case Studies provides case study resources related to managing the supply chain. How, many International companies successfully manage their supply chain and logistics operations is illustrated. Besides our own employees, workers in our suppliers’ factories play a central role in our sustainability program. It was our concern for their working conditions and well-being that led us to establish our "Workplace Standards", the supply chain code of conduct, which also covers workers’ health and safety and provisions to ensure environmentally sound factory operations.

Shortly after this, Nike began the creation of the Fair Labor Association to help improve their operations. Then, they started regular factory audits and publishing detailed factory info. Nike took responsibility for the monitoring of the operations within every link of their supply chain. SC improvements Contd* Innovation with Supply Chain Management: Innovation is helping Nike to achieve its ultimate destination: A truly sustainable supply chain. In order to achieve Nikes long-term vision for sustainability, it recognizes that collaboration with other firms and stakeholders is vital.

case study on failed implementation of erp systems iris efthymiou athens 2014 contents purpose 1. introduction 1.1. stages of implementation 1.2. success factors, failure factors 2. failed implementation—five cases 2.1. hershey’s chocolate corporation 2.2. nike inc. 2.3. Shortly after this, Nike began the creation of the Fair Labor Association to help improve their operations. Then, they started regular factory audits and publishing detailed factory info. Nike took responsibility for the monitoring of the operations within every link of their supply chain.

Smart lessons on designing Enterprise level interventions

How Amazon Is Changing Supply Chain Management. Well, I hope we all enjoyed the Supply Chain Interview Questions, and have learned a thing or two about supply chain. My desire is to give every Supply Chain Professional a better view of what they will possibly face in their next supply chain interview. I hope I have done justice to most of the Supply Chain Interview Questions asked., One of the driving forces behind that transformation is its innovative and highly efficient supply chain. Amazon’s continuous efforts to deliver products to the customers in the shortest possible time are putting intense pressure on other retail industry giants across the globe and thus changing the way supply chain management works..

The Business Case for a Sustainable Supply Chain. Besides our own employees, workers in our suppliers’ factories play a central role in our sustainability program. It was our concern for their working conditions and well-being that led us to establish our "Workplace Standards", the supply chain code of conduct, which also covers workers’ health and safety and provisions to ensure environmentally sound factory operations., Case Study: Nike’s Supply Chain: Failure and Eventual Success 2. What factors led to the i2 Technologies implementation being a highly complex project? Were the increased complexities really necessary? I think to improve somewhat fragmented and failing demand forecasting and order activities in Nike..

The Sustainable Supply Chain Harvard Business Review

Recent Supply Chain Case Studies from Logistics Viewpoints. classic case of green marketing. In this case study of Patagonia’s organic cotton line, the implementation and enforcement of environmental and labor standards the company uses will be evaluated. This paper will travel through Patagonia’s global supply chain to explore the 19-5-2011 · In 1995, Nike and Levi-Strauss (Levis) surprised the business community by publishing their supplier lists. This paper describes case studies of Nike and Levis, tracking the evolution from resistance to supply chain transparency through to the decision to be industry leaders in factory disclosure..

The Business Case for a Sustainable Supply Chain DELL Making Business Mutual Case Study 1│12 May 2017 This is a descriptive case study, based on publicly available materials as well as on the information shared by the company described. A Natural Step Case Study NIKE FROM HUMBLE BEGINNINGS TO GLOBAL PLAYER . Re-named Nike, Nike drafted its first code of conduct for contract labor in 1991 and Removing PVC required cooperation throughout Nike‟s supply chain and innovation from design and production teams.

Besides our own employees, workers in our suppliers’ factories play a central role in our sustainability program. It was our concern for their working conditions and well-being that led us to establish our "Workplace Standards", the supply chain code of conduct, which also covers workers’ health and safety and provisions to ensure environmentally sound factory operations. Besides our own employees, workers in our suppliers’ factories play a central role in our sustainability program. It was our concern for their working conditions and well-being that led us to establish our "Workplace Standards", the supply chain code of conduct, which also covers workers’ health and safety and provisions to ensure environmentally sound factory operations.

15-3-2016В В· Laura Cronenberg, the CEO of Tots & Teens, sipped her black tea in the lounge of Shahjalal International Airport and took some time to collect herself before her flight departed. The past few days 17-5-2013В В· Nike's vision of a lean, green, equitable and empowered sustainable supply chain required a fundamental shift in business relationships, but is now embedded within the new Manufacturing Index.

Case Study: Nike’s Supply Chain: Failure and Eventual Success 2. What factors led to the i2 Technologies implementation being a highly complex project? Were the increased complexities really necessary? I think to improve somewhat fragmented and failing demand forecasting and order activities in Nike. In this instance, Nike will need to upturn how their Nike supply chain functions in order to give consumers what they want, when they want it, and where they want it. “The consumer today expect a premium experience, with innovative product and services delivered faster and more personally,” said Mark Parker, Chairman, President, and CEO of

Supply Chain Management-Nike 1. Supply Chain Management Corina Botnarevschi, Ehab Etani, Akbar Khan, Amir Garranah 2. It started with a handshake. Two visionaries, Bill Bowerman and his University of Oregon runner Phil Knight, thought they could do a better … One of the driving forces behind that transformation is its innovative and highly efficient supply chain. Amazon’s continuous efforts to deliver products to the customers in the shortest possible time are putting intense pressure on other retail industry giants across the globe and thus changing the way supply chain management works.

Answer Of Question no 3 Yes Nike been subjected to false statement lawsuits, As Mr Marc Kasky sued Nike in April, 1998 for its wrong behavior with the labors. for … The strategic contribution of supply management is measured not only in savings made, but also in increased shareholder value (Niezen, Weller & Deringer, 2007). Nike and Adidas are two global companies try to improve their competitive advantage through strategically managing and utilizing their supply chain.

The sub-regions who are more acquainted with other subsidiaries within their region will easily intervene and resolve supply chain hiccups before they escalate in magnitude. Nike uses the Enterprise Resource Planning (ERP) software, SAP to manage all their inventories, deliveries, logistics and … NIKE ERP IMPLEMENTATION - Free download as PDF File (.pdf), Text File (.txt) or view presentation slides online. The document summarizes the rollercoaster ride project of ERP implementation at NIKE and emphasises on the Do's and Dont's of ERP implementation.

Supply Chain Excellence in the Pharmaceutical Industry: Novartis – A Case Study by Gourav Narayan Mukherjee Bachelor of Science in Systems Analysis University of Miami, Miami, FL Submitted to the Zaragoza Logistics Center in Partial Fulfillment of the Requirements for the Degree of MASTER OF ENGINEERING IN LOGISTICS AND SUPPLY CHAIN MANAGEMENT The following case study negotiator pdf outlines Nikes experience in developing and implementing various.Aug 6, 2012. nike supply chain case study pdf Download case study PDF to read moreThe Marketing men at Nike would like us believe that the brand is more than a product, it is

To assure quality and accuracy each case study is carefully reviewed. A case study is a written or recorded, detailed analysis of some targeted management issues, for the purpose of noting success or failure to used as a benchmark for education, research, and/or planning. Download a Supply Chain Management Case Study in pdf format: Get the quality Nike & Pestle Analysis Case Study writing help at affordable price. Since the 1990s, due to the complicated supply chain management, Nike, Inc. started focusing on creating such products which would be better for the athletes, business and also the

Research Methodologies in Supply Chain Management 111 Method Mean Std. DeviationJBL 1978-1993 Survey 3.78 1.13 54.3% Interview 3.78 1.11 13.8% Case Study 3.76 1.24 3.2% 9-4-2018 · Supply chain theory is not always practical. When it comes to improving operations, supply chain case studies often provide more value. What follows are ten supply chain case studies published over the last year in Logistics Viewpoints that provide a …

Case Study: Nike’s Supply Chain: Failure and Eventual Success 2. What factors led to the i2 Technologies implementation being a highly complex project? Were the increased complexities really necessary? I think to improve somewhat fragmented and failing demand forecasting and order activities in Nike. Get the quality Nike & Pestle Analysis Case Study writing help at affordable price. Since the 1990s, due to the complicated supply chain management, Nike, Inc. started focusing on creating such products which would be better for the athletes, business and also the